Smart Dust, Biosensors, Polymers For Geoengineering And The Multinational Corporations That Manufacture Them

In this article, I am discussing geoengineering operations, polymers, biosensors and smart dust that can be aerosolized - or injected via medical vaccination programs. First, those agencies and people who deny geoengineering - our government is studying these modalities, so has full knowledge of them:

The US government has for the first time authorized funding to research geoengineering, the controversial idea that we could counteract climate change by reflecting heat away from the planet. The $1.4 trillion spending bills that Congress passed this week included a little-noticed provision setting aside at least $4 million for the National Oceanic and Atmospheric Administration to conduct stratospheric monitoring and research efforts. The program includes assessments of “solar climate interventions,” including “proposals to inject material [into the stratosphere] to affect climate.” President Donald Trump is expected to sign the sweeping appropriations bills today.

We know that smart dust has been utilized for military purposes:

What Is Smart Dust And How Is it Used?

Polymer and hydrogels can self assemble and be used as devices:

The military contracted many different multinational corporations for their “wearable” biosensor uses:

Biosensors and smart dust can also become body dust. The IEEE explains:

Body Dust: Well Beyond Wearable and Implantable Sensors

Over the last 20 years, the field of Smart Dust has been proposed and demonstrated. Almost in the same period, implantable and wearable sensors for human monitoring have been actually successfully introduced in the market. The present research about Smart Dust is actually in the field of Dust for brain applications (Neural Dust) or for metabolism monitoring (Body Dust). Aim of this feature article is to review all the developments presented so far in literature, and then define the next steps and challenges. First, we see the field of Smart Dust and, then, its application to human sensing. The paper starts from details about the early phases of the research in the area, and first developments. Then, it reviews the recent advancements in the field, for then closing with the definition of the still-open challenges for realizing motes that could spread in human body as thousands of individual sensors in a kind of sensing active network capable to provide telemetry from inside the body. The Body Dust concept discussed in this article is well beyond the present concepts of wearable or implantable devices. These last are actually entering into the market to provide personalized and more precise medicine to human health, while the Body Dust concept definitely represents the future of humans monitoring, still opens to scientific explorations.

If you do not believe governments around the world have been involved in weather modification warfare for decades, here is a good list of patents that says otherwise: Geoengineering: List of weather modification patents 1920-2018

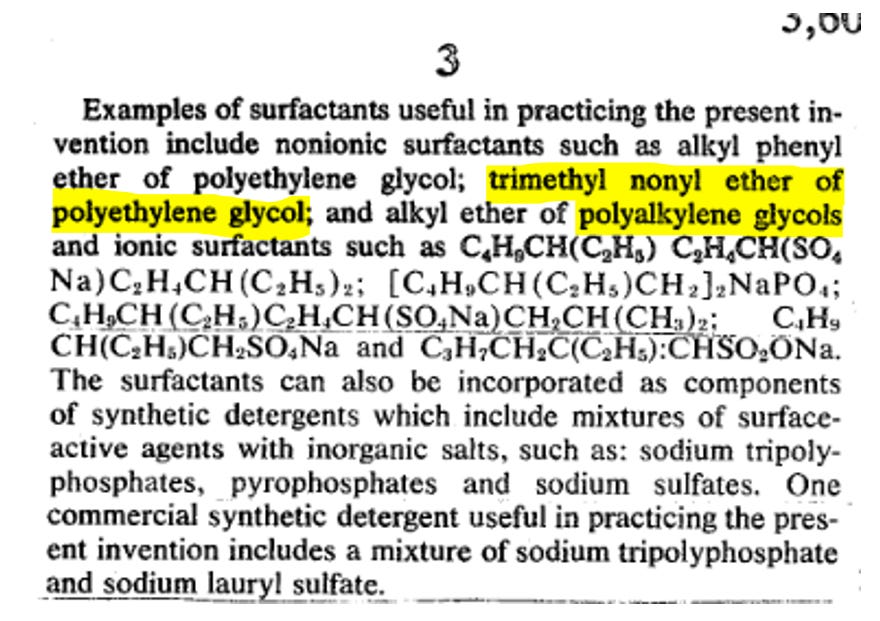

Here is a patent that discusses the use of polymer as a successful way to modify the weather, specifically polyethylene glycol derivatives which is also used in the C19 bioweapons lipid nanoparticles:

Hercules, Inc. was a chemical and munitions manufacturing company based in Wilmington, Delaware, United States, incorporated in 1912 as the Hercules Powder Company following the breakup of the DuPont explosives monopoly by the U.S. Circuit Court in 1911.

DuPont continues to manufacture polyethylene

These polymers can be integrated with biosensors and soft robotics for smart materials:

Stimuli-responsive coordination polymers toward next-generation smart materials and devices

Historical background of DuPont - note nylon production by DuPont - nylon is a polyamide, which is what we found in human blood and is also mentioned as stealth nanoparticles in the Moderna patent:

DuPont, Warriner had a top-secret hand in history

Warriner and DuPont were key players in the Manhattan Project – the secret development of the atomic bomb. DuPont, already supplying nylon for parachutes and nearly half of the TNT U.S. forces would use, built the vast nuclear complex and supporting city in Hanford, Wash., where the plutonium was created for the second bomb dropped on Japan. Warriner oversaw construction of one of the long, thick concrete processors in which the man-made element was produced.

These chemical giants have a long history of poisoning the planet, our food supply, our blood:

DuPont, Chemours and Corteva Reach $4 Billion Settlement on ‘Forever Chemicals’ Lawsuits

Today DuPont, Chemours and Corteva announced a cost-sharing agreement worth $4 billion to settle lawsuits involving the historic use of the highly toxic “forever chemicals” known as PFAS. The Environmental Working Group has documented the decades-long deception of chemical companies like DuPont burying the truth that PFAS build up in our blood and present risks to human health. EWG created a timeline that shows by the 1960s, animal studies conducted by DuPont revealed that PFAS chemicals could pose health risks.

“For decades, these corporations have knowingly contaminated our drinking water, food supplies and the blood of virtually every person on the planet with these highly toxic chemicals,” said Scott Faber, EWG’s senior vice president for government affairs. “It’s long past time that the polluters pay for their malicious drive toward profits over public health.”

DuPont is manufacturing Elastomers. These are:

These are used for soft robotics:

A large-strain and ultrahigh energy density dielectric elastomer for fast moving soft robot

Dielectric elastomer actuators (DEAs) with large actuation strain and high energy density are highly desirable for actuating soft robots. However, DEAs usually require high driving electric fields (>100 MV m−1) to achieve high performances due to the low dielectric constant and high stiffness of dielectric elastomers (DEs). Here, we introduce polar fluorinated groups and nanodomains aggregated by long alkyl side chains into DE design, simultaneously endowing DE with a high dielectric constant and desirable modulus. …Using our DE, soft robots reach an ultrafast running speed of 20.6 BL s−1, 60 times higher than that of commercial VHB 4910, representing the fastest DEA-driven soft robots ever reported.

These are also integrated with biosensing capabilities:

Microscale organisms and specialized motile cells use protein-based spring-like responsive structures to sense, grasp and move. Rendering this biomechanical transduction functionality in an artificial micromachine for applications in single-cell manipulations is challenging due to the need for a bio-applicable nanoscale spring system with a large and programmable strain response to piconewton-scale forces. Here we present three-dimensional nanofabrication and monolithic integration, based on an acrylic elastomer photoresist, of a magnetic spring system with quantifiable compliance sensitive to 0.5 pN, constructed with customized elasticity and magnetization distributions at the nanoscale. We demonstrate the effective design programmability of these ‘picospring’ ensembles as energy transduction mechanisms for the integrated construction of customized soft micromachines, with onboard sensing and actuation functions at the single-cell scale for microrobotic grasping and locomotion. The integration of active soft springs into three-dimensional nanofabrication offers an avenue to create biocompatible soft microrobots for non-disruptive interactions with biological entities.

DuPonts systems are used for human implantation using polymers, silicone and silica as chemical components. Note high levels of silicone were also found in the C19 bioweapons by Dr Geanina Hagima via Mass Spectroscopy. BREAKING NEWS: New Analysis Of C19 Bioweapons: No MRNA, But Toxic Metals and Silicone. Dental Anesthetics & Pneumovax Also Contain Silicone & Metals Used For Nanotech-Interview With Dr. Geanina Hagima

Note these are the technocratic transhumanist technologies that will be used to have AI find new patterns of application for biotechnology - biosensors and soft robotics would be giving AI enormous amounts of data to understand 100 trillion organisms:

Why Bill Gates thinks gene editing and artificial intelligence could save the world

“This is an area that needed these sequencing tools and the high-scale data processing, including AI, to be able to find the patterns,” Gates said. “There’s just too much going on there if you had to do it, say, with paper and pencil to understand the 100 trillion organisms and the large amount of genetic material there. This is a fantastic application for the latest AI technology.” Similarly, “organs on a chip” could accelerate the pace of biomedical research without putting human experimental subjects at risk.

Back to chemical multinational corporation like Dupont and their involvement in healthcare for implantable soft robotics from polymers:

DuPont™ Liveo™ Silicone Elastomers

Liveo™ BioMedical Grade HCR Q7-4750

Silicone Elastomers (Si) FDA 21 CFR

Liveo™ BioMedical Grade ETR Elastomers (Q7-series) are a series of two-part, enhanced-tearresistant (ETR) silicone elastomers that consist of dimethyl and methylvinyl siloxane copolymers and reinforcing silica.

The elastomers exhibit a range of hardness from soft (20 Shore A) to firm (80 Shore A). Each elastomer is supplied as a two component kit (Part A and Part B), equal portions (by weight) of which must be thoroughly blended together prior to use. The elastomer is then thermally cured via addition-cure (platinum-cure) chemistry.

Liveo™ BioMedical Grade ETR Elastomers (Q7-series) are heat-cured high consistency silicone rubbers designed for use by customers fabricating medical devices, including those intended for implantation in humans for less than 30 days.

Note the silica is reinforcing the technology, which is why I warned against the use of zeolite.

Why is this fact that DuPont is fabricating elastomers made from dimethyl and methylvinyl siloxane copolymers and reinforcing silica important? Because the chemical analysis published by Dr Hildy Staninger from 2011 showed the exact same chemicals when she analyzed the mesogens microchips in targeted individuals.

Two polymer network conformations currently exist for LCE materials: Side chain LCE (SCLCE) and Main chain LCE (MCLCE) as illustrated in Figure 1. The side chain conformation has the LC mesogen pendant form the linear polymer network. The main chain LCE has the LC mesogens linked end to end forming a LC polymer which is cross-linked to form the network. Either nematic or smectic LCE may be prepared from side chain and main chain LCE. Some examples are the following: Acrylate side chain LCE – side chain LCE prepared through photopolymerization of acrylate mesogens. (See Figure 2) Siloxane side chain LCE – side chain LCE prepared via hydrosilylation reaction of vinyl mesogen with methyl-hydrosiloxane polymer. 7 Materials of this type also include LCE films/ultra thin films (coatings).3 (See Figure 3) Main chain LCE – main chain LCE prepared via hydrosilylation reaction of vinyl mesogen with methyl hydrosiloxane polymer. (See Figure 4) Polyester/polyurethane (Estane) side chain LCE – side chain LCE segmented polyurethane with functionalized polysiloxane soft segments and tradiotnal MDI/butane diol hard segment. (See Figure 5)

These mesogen nanomachine computerchips Dr Staninger found are exactly what I have found too, in C19 uninjected people who were exposed to shedding. I don’t have access to a lab that would analyze them, neither the tens of thousands of dollars it costs to do so. But I have a microscope and explained the technology and you can see for yourself - these are self assembly nanotechnology microchips.

Are Programmable Nanotechnology Biosensing Mesogen "Computer Chip" Devices Being Self Assembled In C19 Uninjected Blood ? How Dangerous Is Self Spreading Nanotechnology?

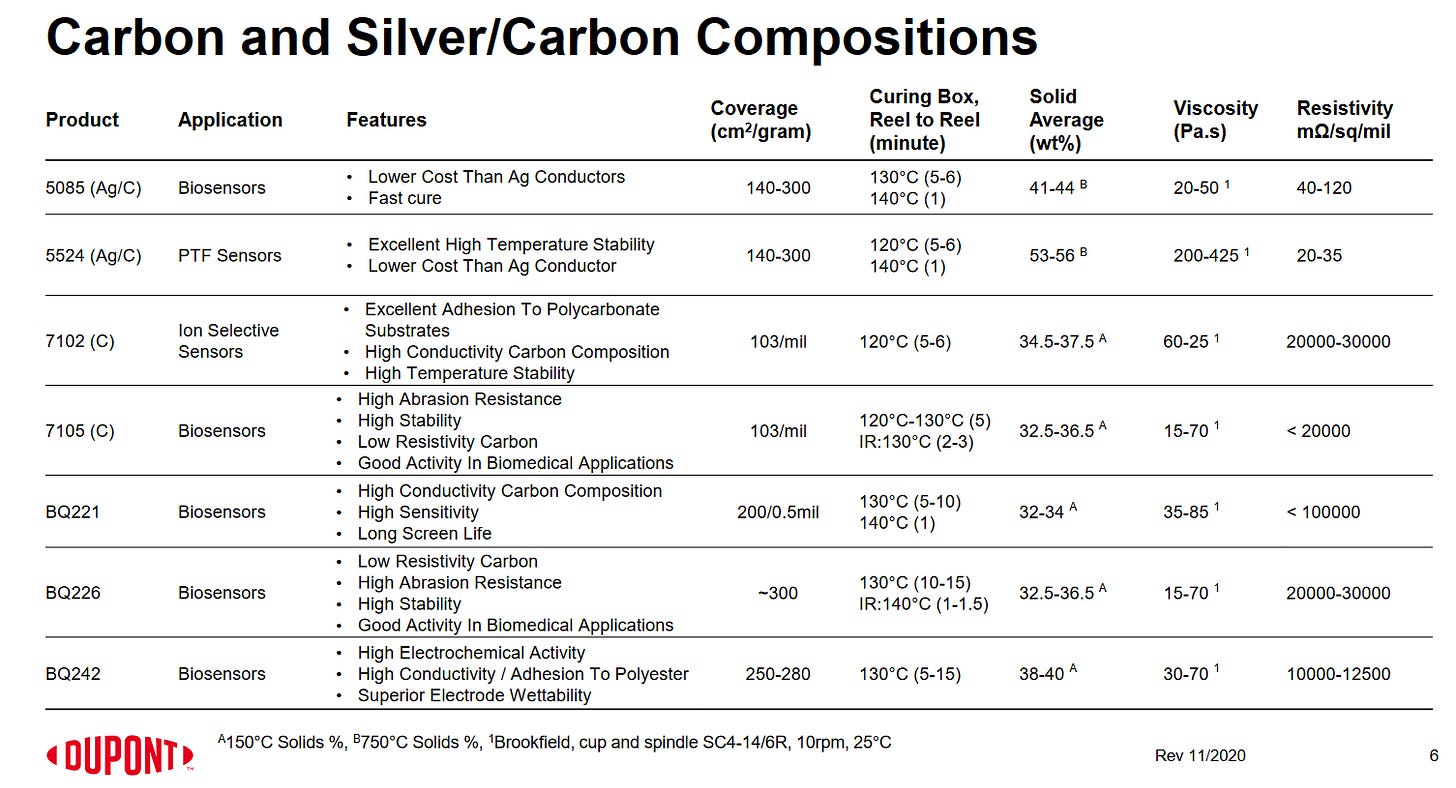

DuPont also creates biosensors for medical surveillance applications: Bio Product Selector Guide

Please note that the biosensors are similar to smartdust. This has been aerosolized even in the Vietnam war and was developed by DARPA, who also had their hand in C19 bioweapon development.

Smartdust[1] is a system of many tiny microelectromechanical systems (MEMS) such as sensors, robots, or other devices, that can detect, for example, light, temperature, vibration, magnetism, or chemicals. They are usually operated on a computer network wirelessly and are distributed over some area to perform tasks, usually sensing through radio-frequency identification. Without an antenna of much greater size the range of tiny smart dust communication devices is measured in a few millimeters and they may be vulnerable to electromagnetic disablement and destruction by microwave exposure.

The concepts for Smart Dust emerged from a workshop at RAND in 1992 and a series of DARPA ISAT studies in the mid-1990s due to the potential military applications of the technology.

Summary:

Geoengineering patents describe polyethylene glycol and other polymers for weather modification. These are the same chemicals used in medical warfare via C19 bioweapons. Biosensors can be used for medical or military surveillance purposes. My recent research that even grass fed unvaccinated beef is contaminating us poses further questions.

Someone is manufacturing these things that poison humanity. Elastomer polymers with silicone and silica were found to be the chemical components of self assembly microchip mesogen nanomachines in targeted individuals. It is worth while learning more about these multinational corporations that are contractors for the military and have been involved in poisoning our planet, food and water - and yet are the major manufacturers for biosensing healthcare applications and implantable polymer chemistry.